INSPEKTIONSSYSTEME AUF EINEN BLICK

MOBIL

Kanal-Inspektionssysteme von DN100 bis DN1000 mit manuellen oder automatischen Kabeltrommeln mit bis zu 300m.

Zur ProduktseiteInspiziere mobil

Einfach, schnell und MOBIL mit einem vollwertigen Inspektionssystem arbeiten. Normgerechte Inspektionsberichte erstellen und von der Baustelle aus direkt teilen.

- Einsatzbereich DN100 bis DN1000

- 100m, 200m oder 300m

- Über 80 Kataloge

HAUPTKANAL

Kanal-Inspektionssysteme von DN100 bis DN2000 und bis 500m im Hauptkanal, für Kanal-TV Fahrzeuge.

Zur ProduktseiteDas All-in-One für Inspektionen

Egal welches Einsatzgebiet - für alle Herausforderungen des Inspektionsmarkts bestens gerüstet:

- Einsatzbereich DN100 bis DN2000

- 300m oder 500m Lösungen

- Werkzeugloses Rüsten

- Komplettsysteme in 3,5 Tonnen Fahrzeuge

SATELLITENSYSTEME

Satelliten Inspektionssysteme von DN150 bis DN2000. Befahre 300 m Hauptkanal und 45 m in Anschlussleitungen.

Zur ProduktseiteWEITER, SCHNELLER - BESSER

Nicht nur im Kanal, tausche selbst Verschleißteile. Das komplette Inspektionssysteme ist für effiziente Einsätze optimiert und daher werkzeuglos um- und aufrüstbar:

- Einsatzbereich von DN150 bis DN2000

- Umrüsten in unter einer Minute

- 30m/Minute (50cm/Sekunde) im Hauptkanal

- 7m/Minute (11,67cm/Sekunde) in Anschlussleitungen

SCHIEBESYSTEME

Schiebekamerasystem für DN50 bis DN300 und bis zu 100m. Mobiles inspizieren mit Tablet oder mobiler Bedieneinheit.

Zur ProduktseiteInspizieren in allen Lagen

Das modulare Schiebesystem ist als einfaches Inspektionssystem oder als professionelle Dokumentationslösung einsetzbar.

- Einsatzbereich DN50 bis DN300

- Axial- und Schwenkkopfkameras

- Ultraleichtes System mit bis zu 6h Akkulaufzeit

Kanalinspektionssysteme für den täglichen effizienten Einsatz

Wir entwickeln unsere Produkte zusammen mit unseren weltweiten Kunden und Partnern, um den Inspekteuren ein einfaches und effizientes arbeiten im Kanal (ATEX und non-ATEX) zu ermöglichen. Intuitive Bedienung und werkzeugloses Rüsten unserer Kanalinspektionstechnik sind unser Hauptaugenmerk.

KANALINSPEKTIONSSYSTEME DIE WELTWEIT BEGEISTERN

SICHER IN EXPLOSIONSGEFÄHRDETER UMGEBUNG

Kanalinspektionssysteme für ATEX Zonen

Für maximalen Schutz im Abwasserkanal oder in Kanalsystemen von Industriebetrieben entwickeln wir ATEX-Konzepte für Inspektionsanlagen. Hierbei legen wir größten Wert auf die Sicherheit der Anwender unter anderem durch Drucküberwachungen.

Quick-Change-Design (QCD) - einfach und schnell

Für effiziente Arbeitstage und mehr Zeit zur Kanalinspektion entwickeln wir unsere Systeme nach dem Ansatz der Benutzerfreundlichkeit. Hierzu halten wir viele Patente für das werkzeuglose Rüsten (QCD). Dies ermöglicht das Rüsten von Kanalinspektionsanlagen in wenigen und einfachen Handgriffen sogar mit Handschuhen.

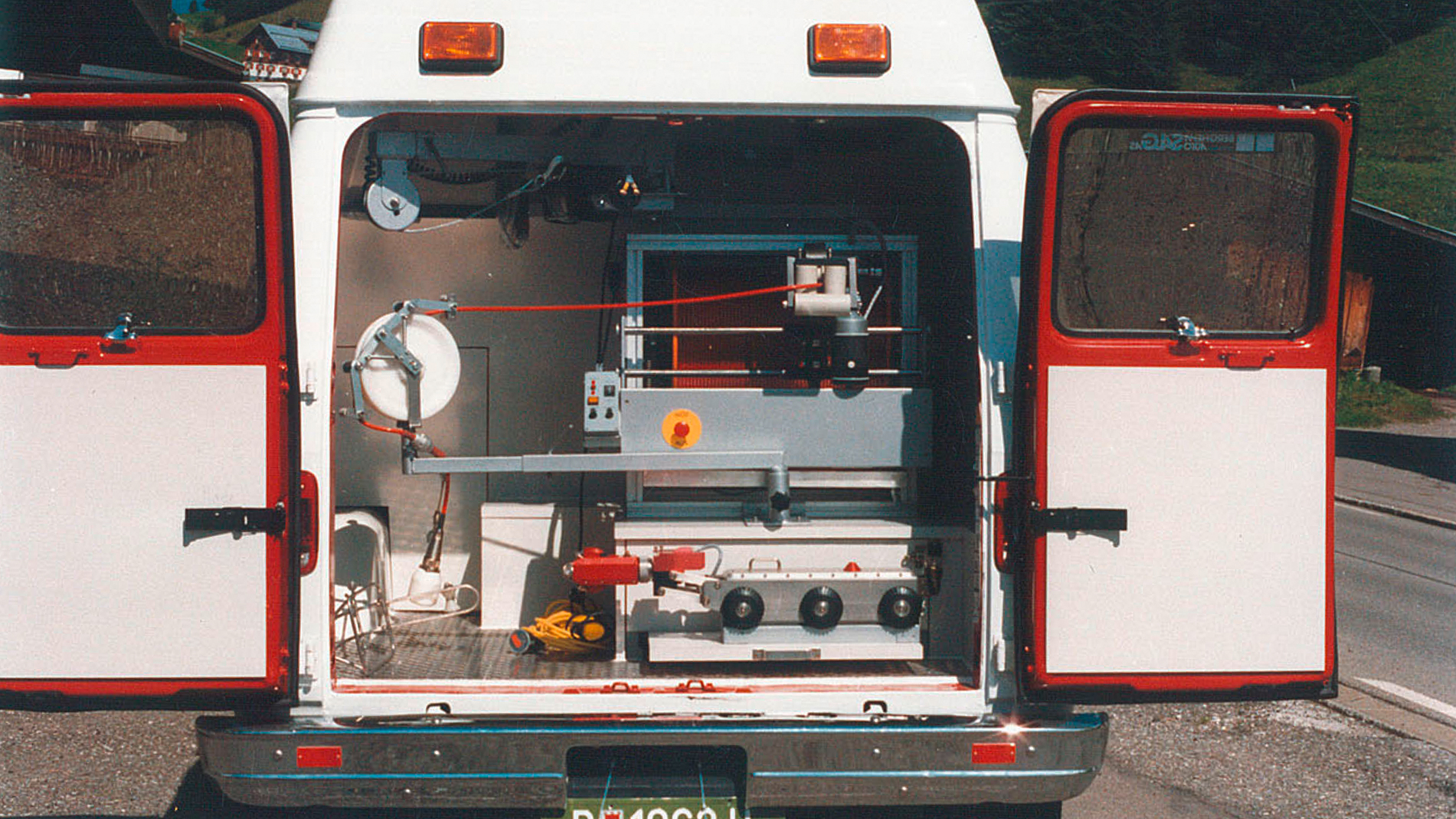

iPEK Fahrzeugausbau

Verstaue in deinem individuell ausgebauten Kanal-TV Inspektionsfahrzeug alles, was du für deine Inspektion benötigst vom Fahrwagensystem bis hin zum Schiebesystem. Dank der leichten und kompakten Bauweise unserer Inspektions-Systeme, ob für Hausanschlüsse, Anschlussleitungen oder Hauptkanal, bringst du diese auch in einem 3,5 Tonnen Fahrzeug gut unter.

Dank der iPEK Partner - erhalten Sie überall Support und Service

Wir und unsere 80 Sales- und Servicecenter weltweit suchen und lösen gemeinsam mit Dir, auch per Ferndiagnose, die Fehler und Probleme. Greife auf Ersatzteilsets zurück und reduziere mit der Expresslieferung Standzeiten. Lerne mit uns und dem iPEK Studio wie die Lebensdauer der Systeme durch regelmäßige Wartung und Instandhaltung verlängert werden kann.