ROVION SAT II CONQUERS THE BENELUX MARKET

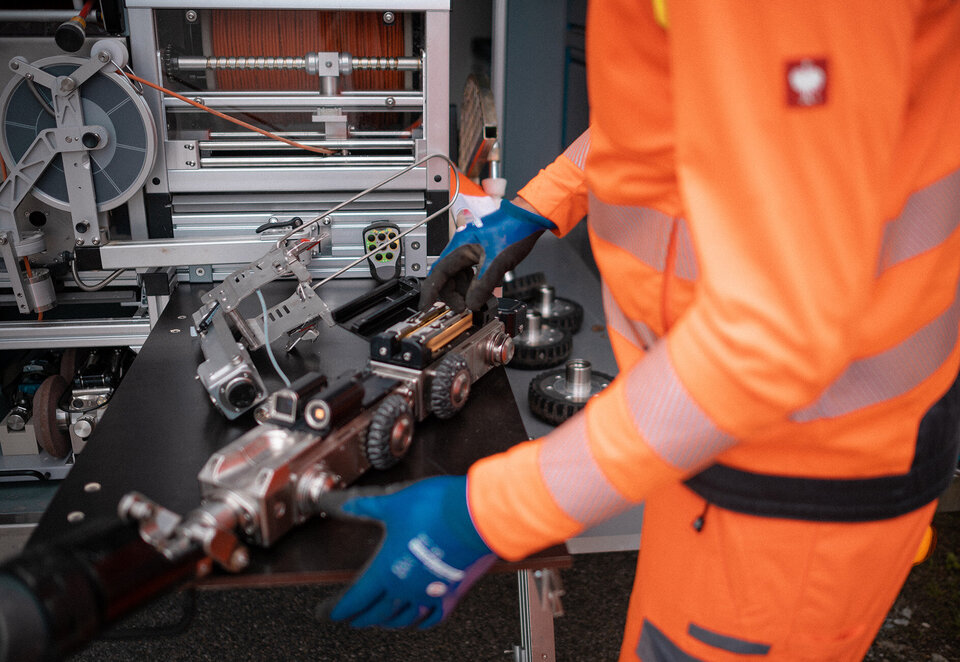

Van de Kreeke Leidngtechniek’s new iPEK lateral inspection system ROVION SAT II makes inspecting laterals from the main sewer made easy.

The sewer rehabilitation company Van de Kreeke has acquired iPEK’s ROVION SAT II system in the application range from DN150 to DN2000 – It has proved to be a worthwhile investment for the specialist. "Since the purchase in June, the RX140SAT II has been on the road almost every day," says René Knols, the company's technical director.

Innovation for Van de Kreeke

As one of the leading construction companies, Van de Kreeke always has its finger on the when it comes to innovation. What started 70 years ago as a traditional road construction company has now developed into a multifaceted business: In addition to construction, asphalt paving and concrete technology, Van de Kreeke also specializes in sewer cleaning and sewer inspections.

ROVION SAT II has changed how Van de Kreeke carries out trenchless inspections. "In this respect, the acquisition of this new lateral system is of course an important step. The RX140SAT II lateral crawler can inspect laterals from the main sewer. The technique of conducting inspections from the main line dates back to the early 1990s but inspecting all the way - so to speak - to the toilet bowl is a more recent innovation," says Knols.

The Benefit of Main Line Sewer Inspection

Van de Kreeke is active in both the Netherlands and Belgium. In Belgium, trenchless inspections are already standard, in contrast to the Netherlands. Knols explains the reasons for this as follows: "This has mainly to do with the regulations. In Belgium, every time a new sewer is laid, the laterals must be inspected from the main sewer or the transfer manhole. This is not the case in the Netherlands, but even there they are now realizing the advantages of this inspection technique: If the lateral is inspected from the main sewer, obstacles or defects can be detected more quickly. As far as I know, we are currently the only ones in the Netherlands with such a lateral inspection system."

Ed Goossens adds: "For example, when new asphalt is applied, the condition of the main sewers is checked, but not the laterals. However, to avoid problems, damage, or unnecessary costs, later on, using the lateral truck is a very good idea to check the condition of the connecting pipes in advance."

Goossens is especially impressed by ROVION’s ease of use. Thanks to the Quick-change Design (QCD) of the entire system, the crawler can be adjusted to fit the required pipe size in under a minute.

During the new purchase, our partner SewerVision briefed the team in detail and shared tips and tricks for even faster workflows.

Worthwile Investment

"Our regular customers are already very enthusiastic. It is certainly not a small investment, but the added value is already clear. Both for the customer and us. Our overall service package is extensive and we are constantly investing in the latest techniques. And that's what makes us so versatile in the construction sector," René Knols sums up.